Why should TrackBot™ be an Apartment Management Committee Members Best Friend?

A gated community or housing society employs staff for the upkeep of the functioning of various amenities. They also need to invest in maintenance of various electro mechanical items - whether its repair or new purchase. As member of a housing society or apartment complex or a gated community Management Committee, it is very important to stay updated of the functioning status of your amenities.

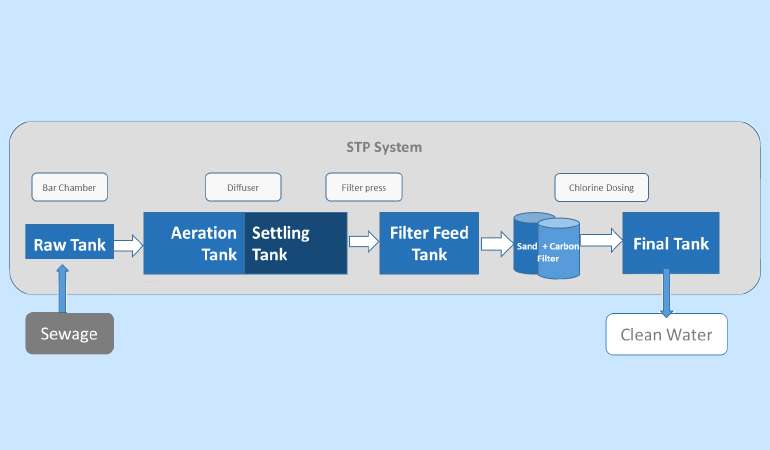

Unexpected equipment failure, especially in Sewage Treatment Plants can cause the breakdown of entire STP system and lead to costly downtime that can impact your residents significantly.

Regular equipment maintenance is the key to preventing catastrophic equipment failure. It can pay off in the long run in the form of increased operational efficiency and reduce cost.

The Importance Of Proper Equipment Service

Proper equipment service is well worth the investment. Here are some of the long-term benefits of preventive equipment maintenance:

- Extend equipment lifespan and reduce the need for having to purchase new equipment.

- Prevent unplanned downtime which can be costly.

- Avoid the need for expensive repairs due to negligence.

- Keeps equipment running without interruption to ensure that amenities are in usable condition.

- Ensure that systems are working efficiently to reduce energy consumption and operating cost.

- Prevent small issues from growing into big problems that are time-consuming and costly to fix since complex repair often comes with a bigger price tag and longer downtime.

What’s Involved In Equipment Service?

The goal of proper maintenance is to ensure that your equipment is running at 100% efficiency as much as possible.

With the aid of the latest technologies, such as smart sensors, cloud computing, and the Internet of Things (IoT), equipment maintenance has gone beyond regularly scheduled visits by technicians.

For example, smart sensors fixed at different equipment can alert estate managers or management committee member of potential issues in real-time so they can be remedied before the problem causes breakdown of a particular amenity.

In addition, a workflow that incorporates daily or weekly inspections, cleaning and monitoring can prevent major problems from developing.

How To Ensure Proper Maintenance Of Your Equipment

By building simple processes into your operation procedures, you can ensure that the equipment is properly maintained:

- Set up processes to analyse the performance data from your systems and monitor their operation so you can become aware of potential issues before they become a problem.

- Provide proper training to technicians and operators so that when a problem is detected, they can recognize the issues and know how to deal with them properly. In addition, the right training can prevent misuse or overuse of equipment to avoid unnecessary repairs.

- Assign responsibility and make specific staff accountable for the proper functioning of the equipment. Empower and educate the right employees to ensure the success of preventative maintenance.

- Implement a maintenance / service schedule and conduct regular inspections to prevent wear-and-tear that can turn into larger issues.

- Establishing a proper equipment maintenance workflow is essential to operate at the highest efficiency. This is not something to skimp on and the effort will pay off in the long run.

- Track the service history, part detail digitally and also keeping the required info of the vendor who repairs the parts in-case of emergency.

How TrackBot™ helps you?

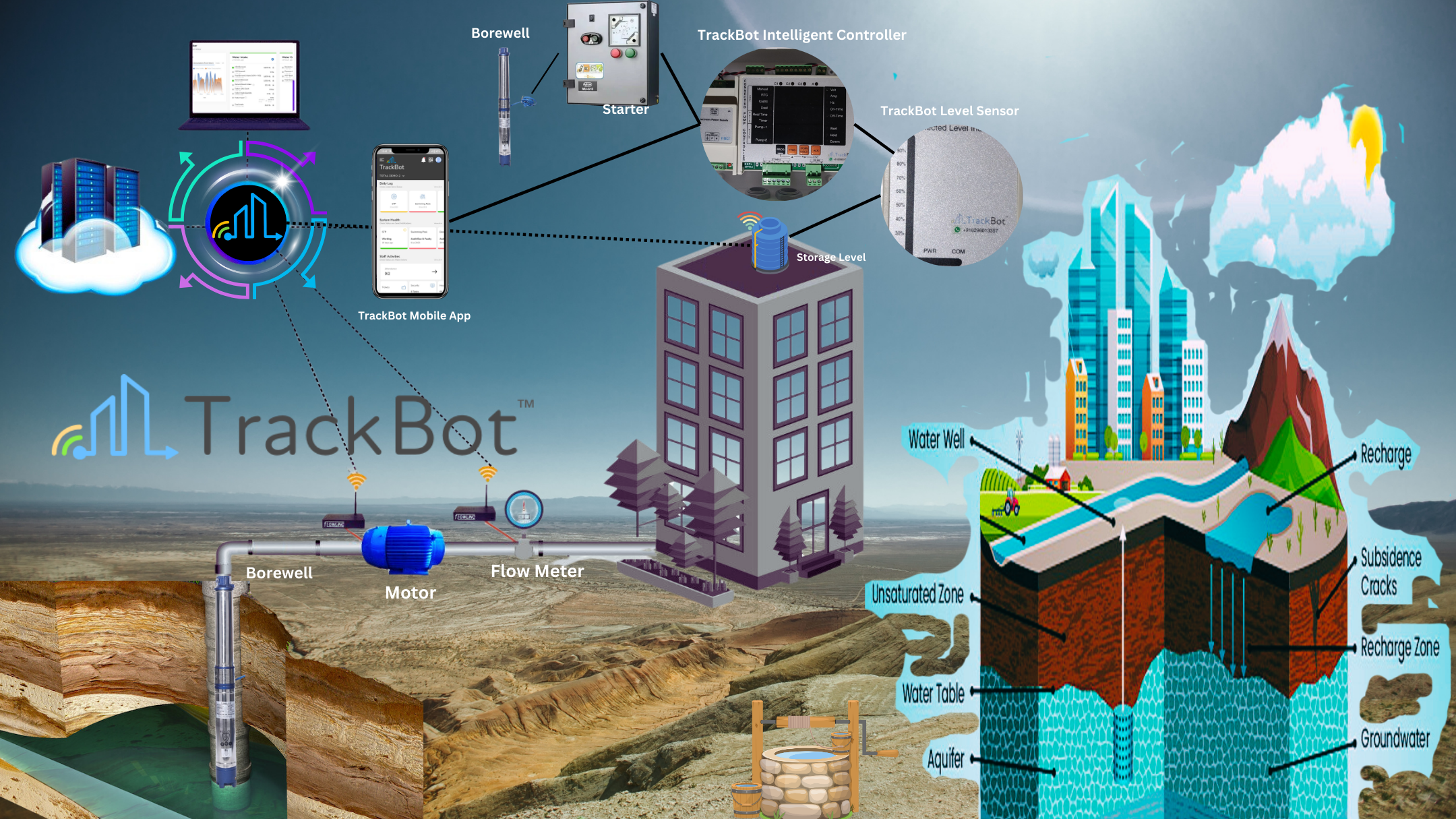

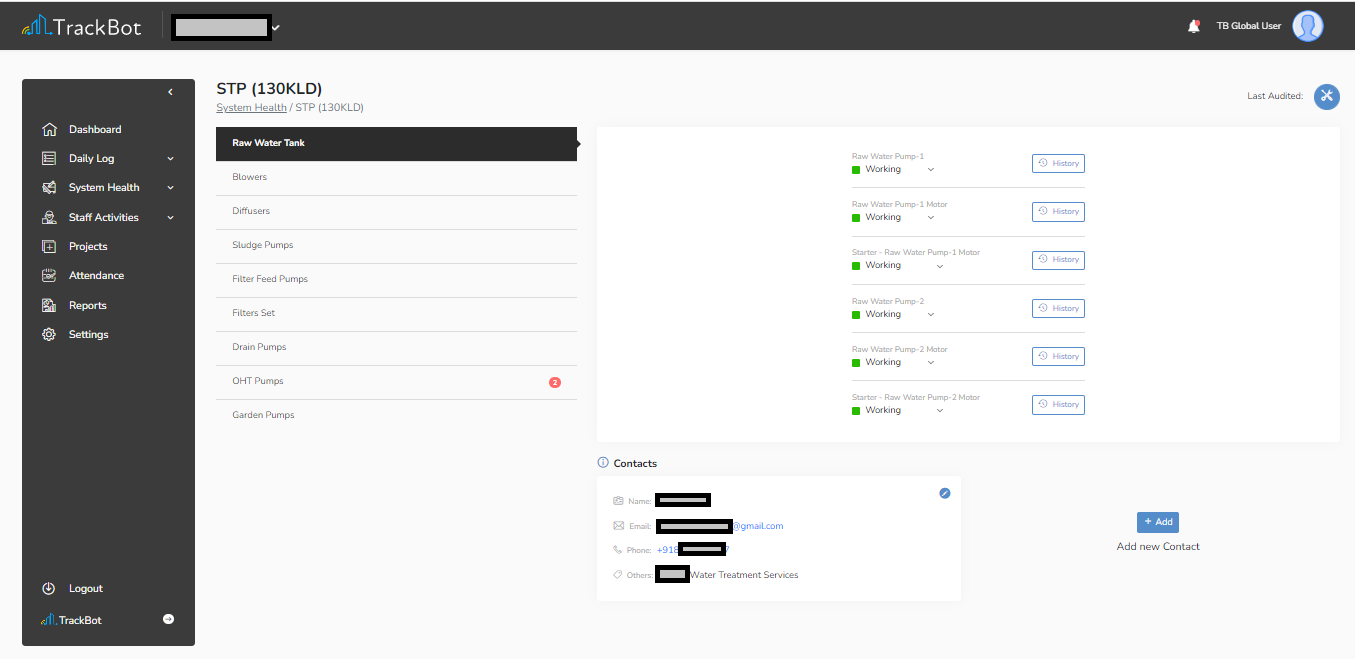

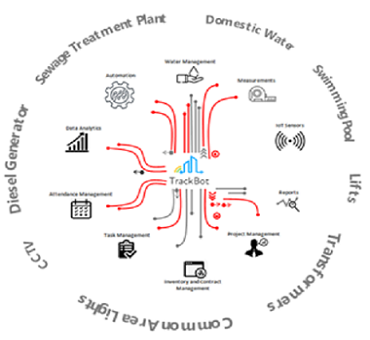

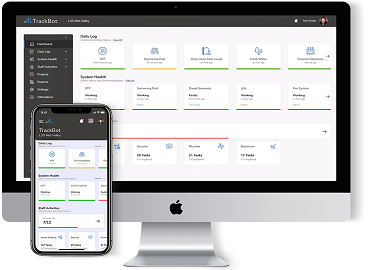

We simplify your day to day monitoring overheads with one integrated platform. With the help of advanced and affordable technologies such as Cloud, Internet of Things you will be able to connect and monitor the system health, daily operational status, component failures, Operator activities, Operator availability, System inventory, Regular service notification in real time through TrackBot™.

TrackBot™ facilitates a simple mechanism to track the details you need like current working status, service and repair history, for easy decision making of each and every equipment installed in your premise such as Motors, Starters, CCTV, Lifts, Common Area lights and much more with the help of sensors like Dissolved Oxygen, pH, TDS, Overhead and Underground tank Water Level, Voltage, Current etc. With TrackBot™ you can also monitor the service history, part details and vendor details by scanning the QR codes attached to the equipment.

So why want to be reactive. Better be proactive with TrackBot™. With our state of the art real-time monitoring solutions, identify and diagnose the issues before they happen by having deeper insights into devices status, operational parameters.