TrackBot Predictive Maintenance: A Game Changer in Asset Management

TrackBot Predictive Maintenance (PdM) leverages data analysis and advanced technologies to anticipate potential equipment failures before they occur, preventing downtime, extending equipment lifespan, and improving operational efficiency.

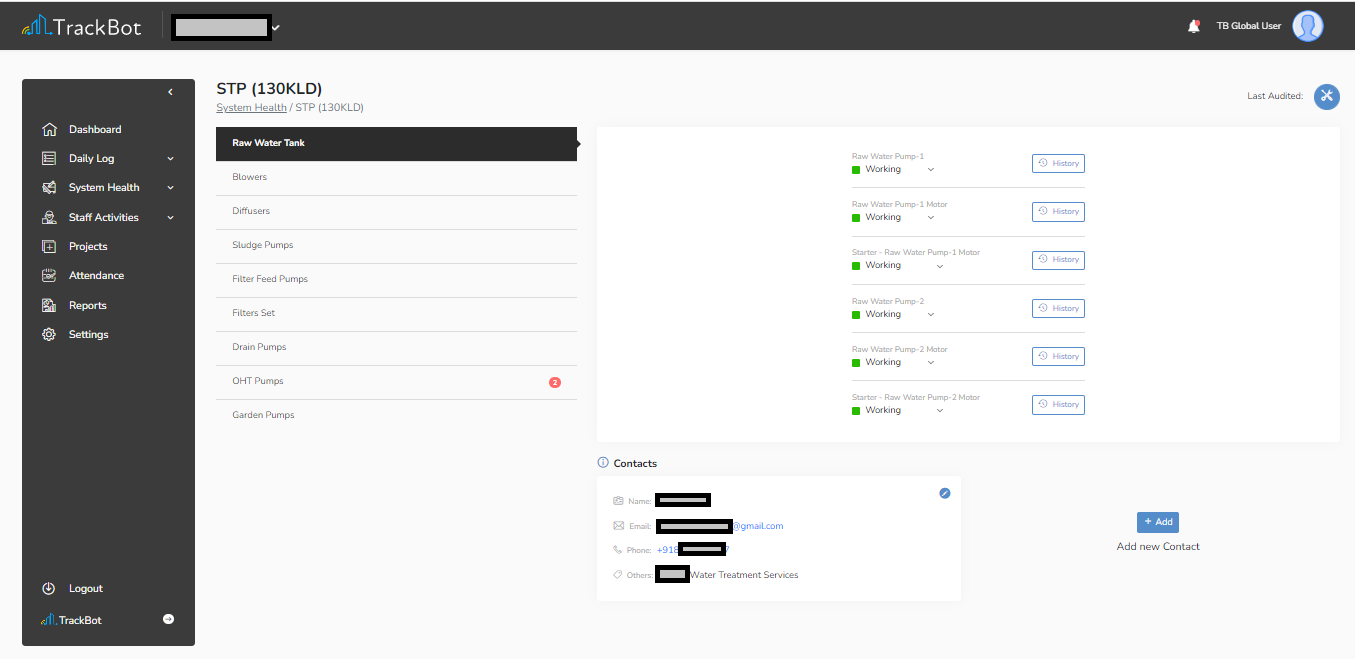

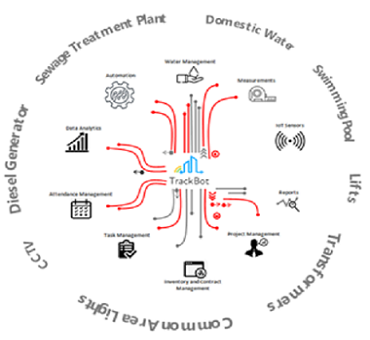

TrackBot’s Predictive maintenance (PdM) is a revolutionary approach to asset management that leverages data analysis and advanced technologies to anticipate potential equipment failures before they occur. Unlike traditional reactive maintenance, which waits for problems to arise before addressing them, TrackBot PdM focuses on proactive, data-driven strategies to prevent breakdowns and optimize asset performance. This would help the facility management companies or association to keep the critical resources such as HVAC systems, Pumps, Blowers, Diesel Generators, Lifts, Transformers, and other critical components in healthy condition always.

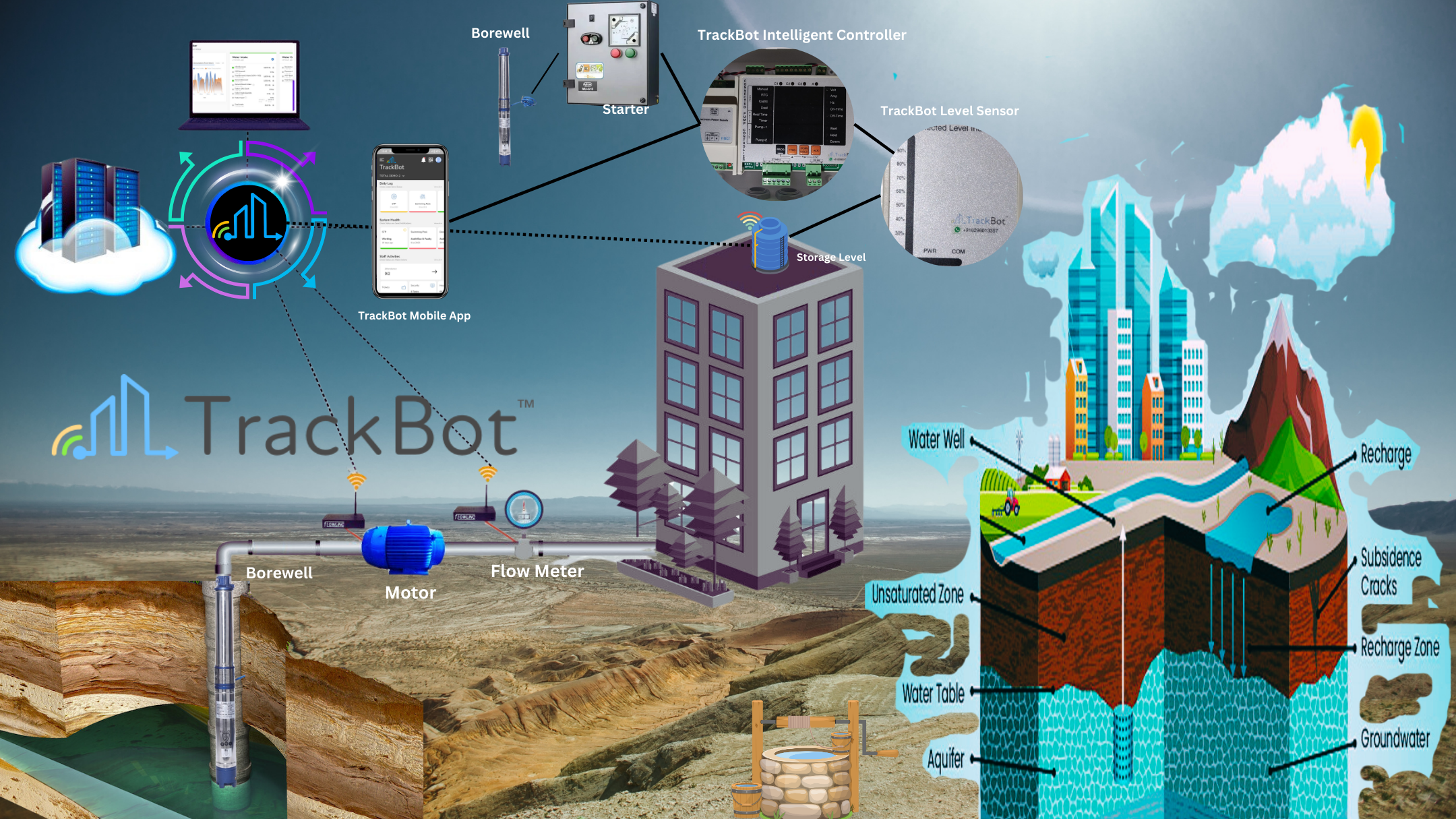

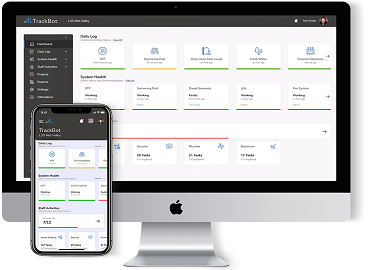

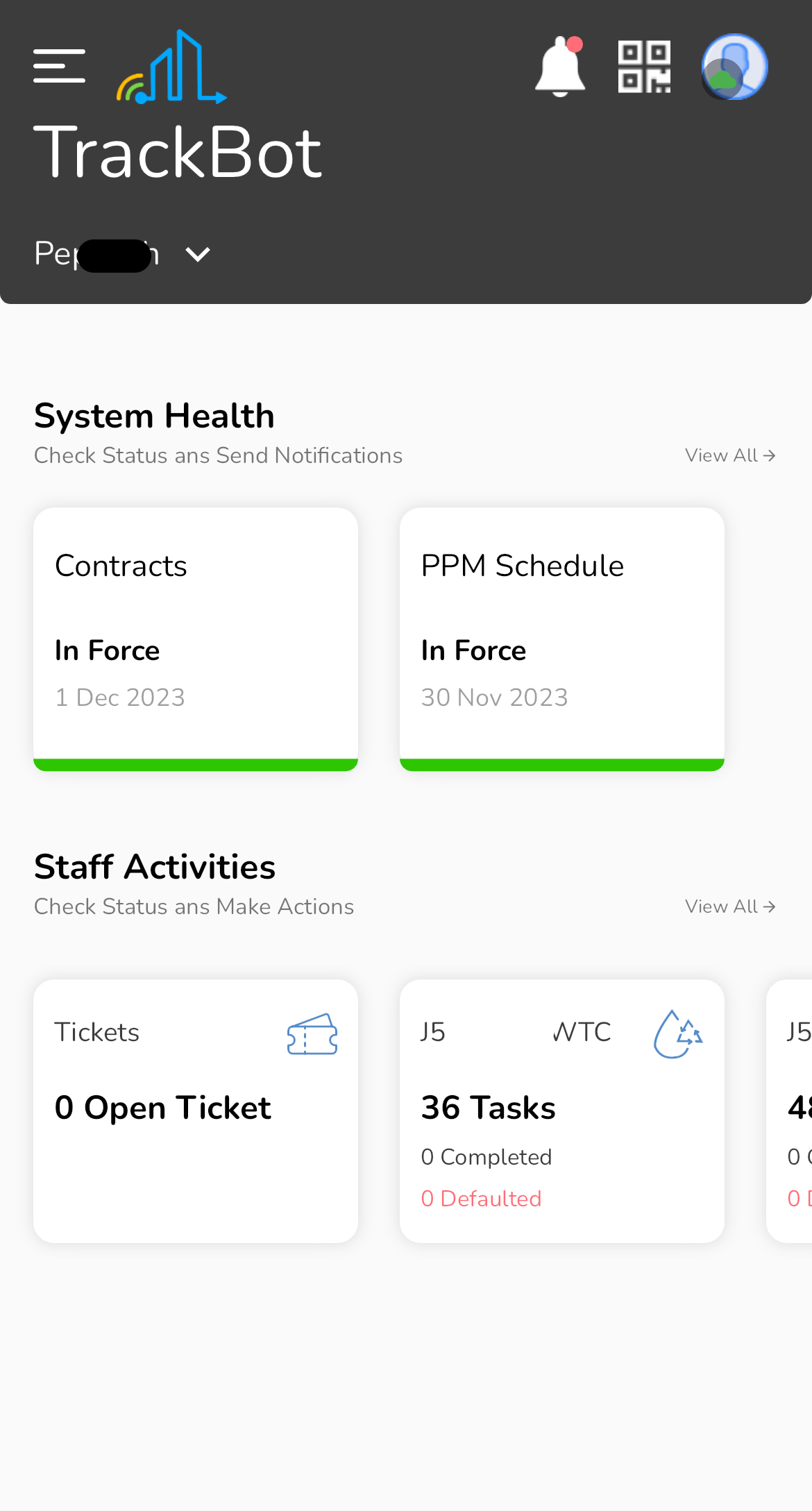

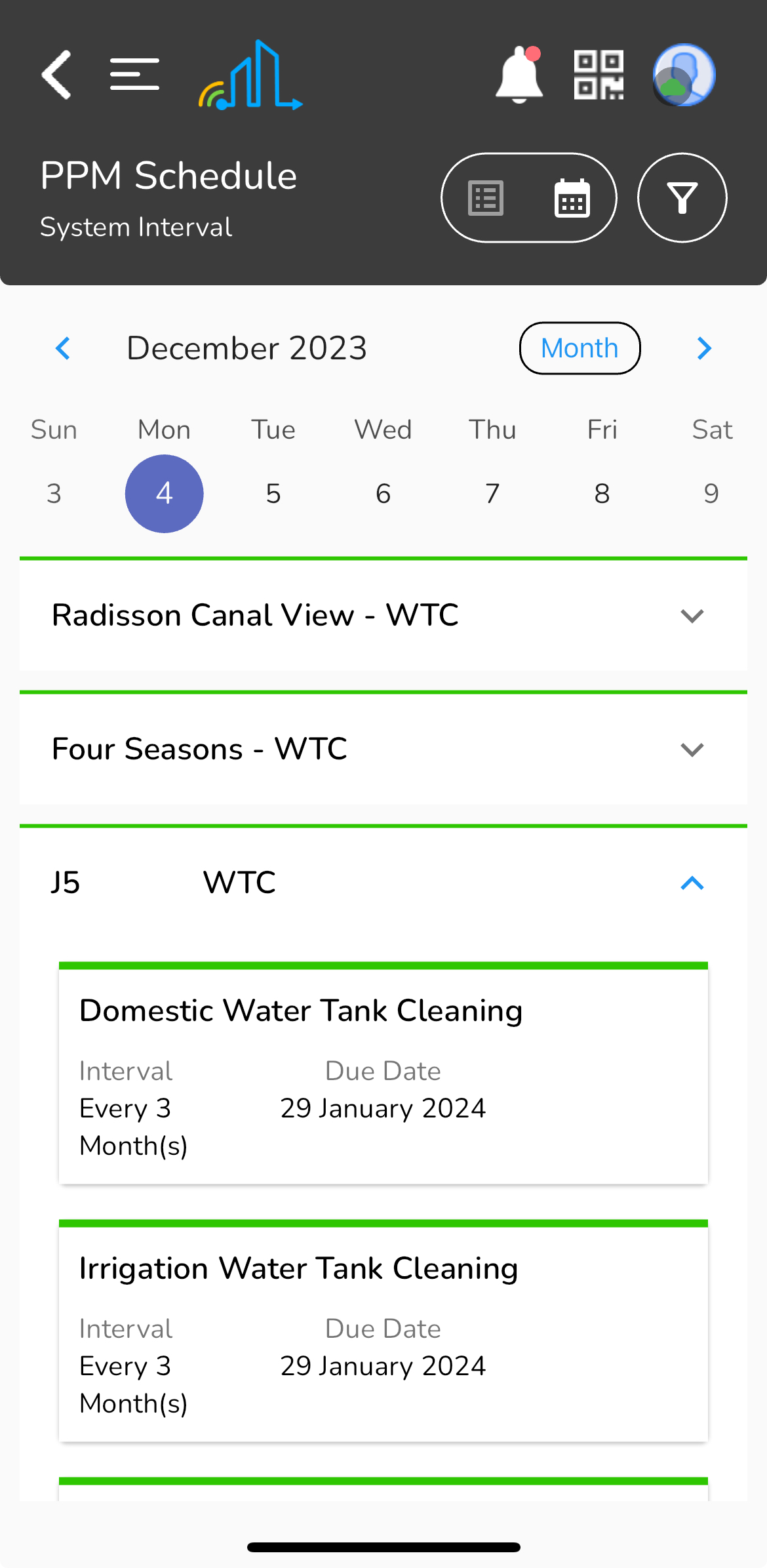

Our cloud-native and device independent application offers a variety of benefits over traditional on-premises software, making it an increasingly popular choice for businesses of all sizes and across countries. Integrated with the famous TrackBot Task Management system, it will become an even more powerful tool for managing the amenities unlike ever before.

Data-driven insights

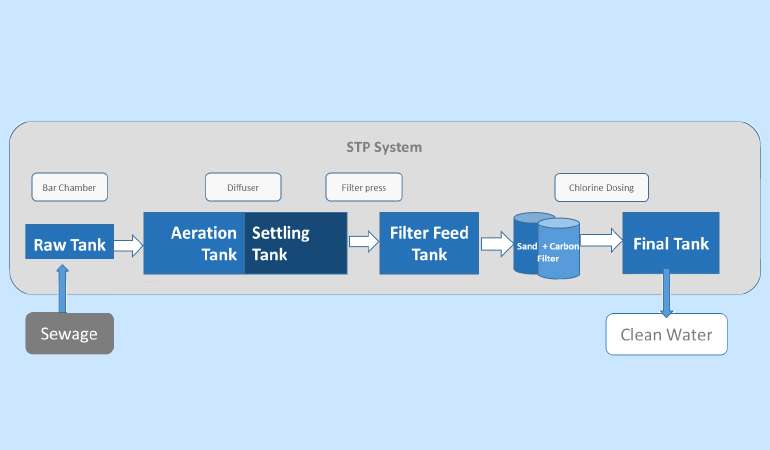

TrackBot’s PdM relies on collecting and analysing data from various sources, including Diesel Generator, Lifts, Blowers, Sensors, Vibration analysis, and operational records, collected automatically or updated by the operators periodically. This data provides valuable insights into equipment health and performance, allowing for the identification of subtle anomalies that may indicate potential issues.

Predictive models

Optional advanced analytics and machine learning algorithms available in TrackBot are employed to analyse the collected data and create predictive models that forecast the remaining useful life (RUL) of equipment. These models enable proactive maintenance interventions before failures occur, minimizing downtime and associated costs.

Proactive intervention

Based on the RUL predictions, TrackBot’s PdM schedules maintenance activities just when they are needed, maximizing equipment uptime and efficiency. This approach eliminates unnecessary maintenance and optimizes resource allocation. This will also help the Facility Management companies to allocate the resources optimally and dynamically, based on their availability and reduce dependency.

There are several benefits of TrackBot’s Predictive Maintenance.

Reduced downtime and production losses:By preventing unexpected failures, TrackBot’s PdM minimizes downtime and ensures uninterrupted production flow, leading to significant cost savings and increased productivity.

Extended equipment lifespan:Regular and timely maintenance based on real-time data helps prevent wear and tear, extending the lifespan of equipment and delaying expensive replacements.

Improved operational efficiency:Optimized equipment performance translates to improved efficiency across operations, leading to reduced energy consumption and optimized production costs.

Enhanced safety:Predictive maintenance helps identify potential safety hazards before they result in accidents, creating a safer work environment for employees.

Data-driven decision-making:TrackBot’s PdM provides valuable insights into asset health and performance, enabling informed decisions for maintenance planning, resource allocation, and future investments.

TrackBot’s PdM is applicable across various industries, including:

Apartments, Tec parks and Facility Management:Monitoring building systems for potential failures to ensure occupant comfort and safety and optimize energy consumption. Key equipment like Diesel Generator, Borewells, Lifts, Blowers, Transformers, etc. for potential failures to avoid downtime and ensure uninterrupted services and associated costs.

Security:CCTV are deployed at every corner these days and they are the key to ensure safety and greatly helpful to backtrack any unfortunate incidents. But at the same time, it’s equally important to ensure that those cameras are working always and recordings are available on-demand.

Energy and Utilities:Predicting maintenance needs for turbines generators, and other critical infrastructure to ensure reliable energy supply.

Manufacturing:Monitoring production equipment for potential failures to avoid downtime and ensure continuous production.

Transportation:Monitoring the health of aircraft, trains, and other vehicles to prevent accidents and optimize maintenance schedules.

Healthcare:Predicting the need for maintenance on medical equipment to ensure patient safety and improve operational efficiency.

The future of TrackBot’s Predictive Maintenance:

With advancements in sensing technologies, data analytics, and AI, TrackBot’s PdM is rapidly evolving and becoming more sophisticated. The future of TrackBot’s PdM promises even greater benefits: Autonomous maintenance:AI-powered systems will automatically analyse data and schedule maintenance tasks without human intervention, further maximizing efficiency and reducing costs.

Real-time monitoring and insights:Advanced sensor technology will enable continuous monitoring of equipment health, providing real-time insights for proactive decision-making.

Cross-functional integration:TrackBot’s PdM will be integrated with other operational systems, such as HVAC, PLM, production planning and energy management, for a holistic and optimized approach to asset management.

Enhanced Security:Integrated with the known CCTC camera features such as barrier crossing alerts, image recognition capabilities, etc., to alleviate security loopholes in the premises.

Overall, TrackBot’s PdM is transforming asset management across industries. Its affordability and proactive and data-driven approach delivers significant benefits, including improved operational efficiency, reduced costs, and enhanced safety. As the technology continues to evolve, there are even greater possibilities for optimizing asset performance and maximizing value using TrackBot platform.

See TrackBot in action on YouTube